Although the industry has come some way in using geometrical modelling, it could make a significant difference if it were used in procurement. How can clients and designers be encouraged to share models at this stage?

In its 2011 Construction Strategy the UK government stated that centrally-procured public-sector projects should achieve BIM level 2. Ten years later, although the industry is making strides in using geometrical models as a form of BIM for design, the use of such models in procurement has not kept pace.

Our 2021 procurement trends survey, Getting Closer to your Supply Chain, shows that the industry’s use of geometrical modelling for tendering purposes is relatively low. The survey, in which 113 UK contractors participated, found that fewer than a third of projects provide geometrical models at tender stage, a proportion largely unchanged since the 2019 survey.

Of those projects that do share models at tender stage, almost 60% are worth at least £60m, just under 30% are between £15m and £60m, and just less than 20% are below £15m. Not using geometrical modelling at tender stage means there is a digital gap through the life of a project.

The Construction Playbook provides a clear and updated direction from the UK government on best practice in construction projects. It advocates a digital strategy using modern methods of construction, early engagement and clear specifications, effective contracting and due diligence during selection. Digitally enabled procurement processes based on the UK BIM Framework are key to fulfilling these objectives.

Benefits and blockers

The survey found the benefits to contractors of receiving geometrical models at tender stage were, from most to least frequently citied:

- design interrogation, including clash detection

- minimising risks and reduced risk allocation

- more efficient take-off of quantities for pricing

- analysis of construction sequencing and optimising buildability.

These factors also offer benefits for clients including less priced risk, quicker tendering and more robust programming. However, while it is a benefit for contractors to be able to interrogate the design, this may also be a barrier to geometrical models being shared from the client and design team’s perspective.

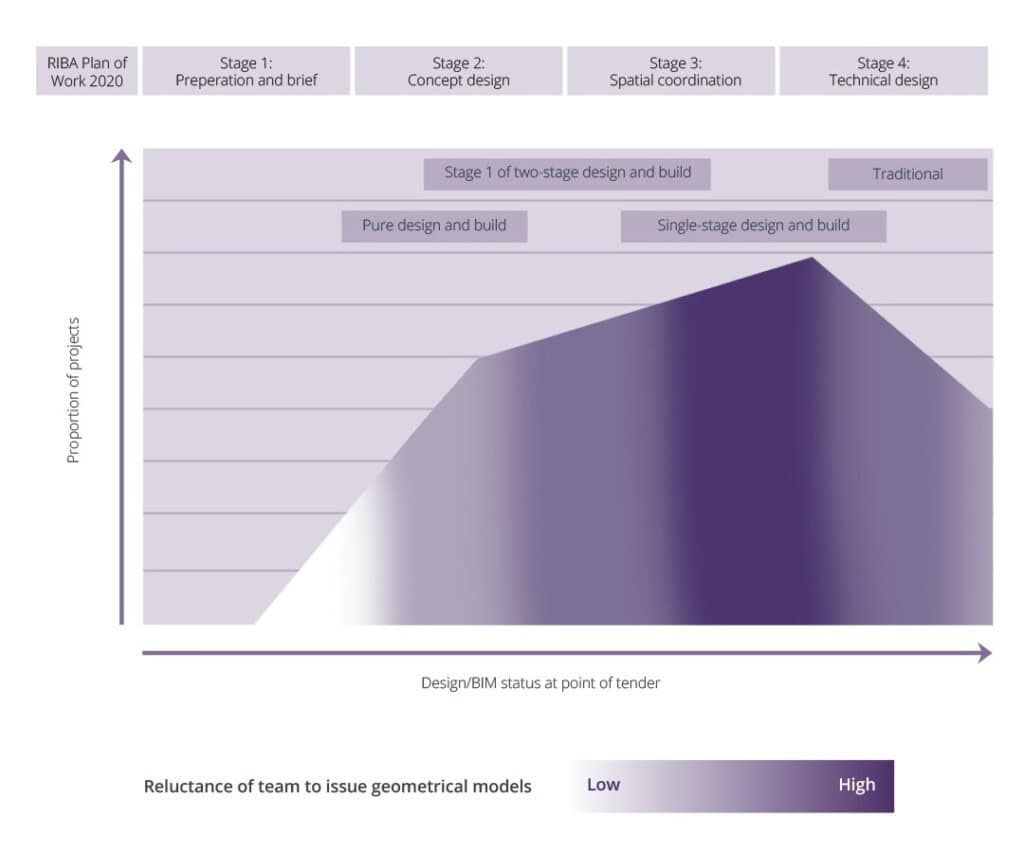

As the first step towards assembling the project team, tendering represents an engagement with the market. It seems odd therefore not to embrace digital collaboration by providing geometrical model files as part of the tender documents. While procurement is often considered a discrete programme phase, it can occur anywhere from RIBA stage 1 to 4. It can also be a phased process, with two stage tendering often offering an opportunity to involve a contractor earlier in the project.

A team’s reluctance to share geometrical models to support the procurement of a contractor can be affected by the perceived risk in doing so. Designers are right to be alert to the status of the model being shared particularly if it is not developed to the extent required given the design stage.

This may be unintended – due to limiting spend on design fees before tender or a prioritisation of programme over design – or simply because the digital design and procurement strategies have not been overlaid. If a tender is issued prior to thorough design coordination, designers may also have concerns that not all clashes have been detected and suitably resolved. The finer points of clash tolerances and the need to address clashes at an appropriate design stage may not be communicated.

In both circumstances, the client and design team may be reluctant to make the models available for external scrutiny, and be concerned that risk may increase if they are shared at tender stage. This reluctance profile varies by the stage of the models. Teams may be less reluctant if models are shared early, as a contractor comes on board for a two-stage process – it will be obvious that the design is less developed and that there is an opportunity to work with the contractor to develop the design prior to finalisation of the tender sum. Likewise, when stage 4 has been concluded there is a far greater willingness to share information models as they are likely to be coordinated. The reluctance profile therefore coincides with a common design stage for procurement activity – stage 3 and early stage 4 – which is shown in Figure 1.

Bridging the digital gap

In order to bridge the digital gap, teams need to communicate effectively with tendering contractors. The difficulty remains that project managers and quantity surveyors may see a geometrical model as a design tool and defer strategy-making to the designers in the team. However, the current edition of the International BIM Implementation Guide, RICS guidance note, reminds us that: ‘BIM [in the form of geometrical modelling] cannot be dealt with at the technology level alone as it has far-reaching implications’, while outlining how it affects the full operating system of a project including processes as well as legal and commercial considerations. As procurement sits at the intersection of these three, surveyors need strategies for integrating all types of information models into procurement and bridging the digital gap.

Fear of miscommunication and misinterpretation are two key issues that can prevent geometrical models being shared. BS EN ISO 19650-2 provides clear direction of information management resources that should accompany tenders and appointments. For geometrical modelling, the National Annex to BS EN ISO 19650-2 provides a means of defining the status and purpose of different information files. Following the principles set out in the standard will prevent miscommunication and misunderstanding.

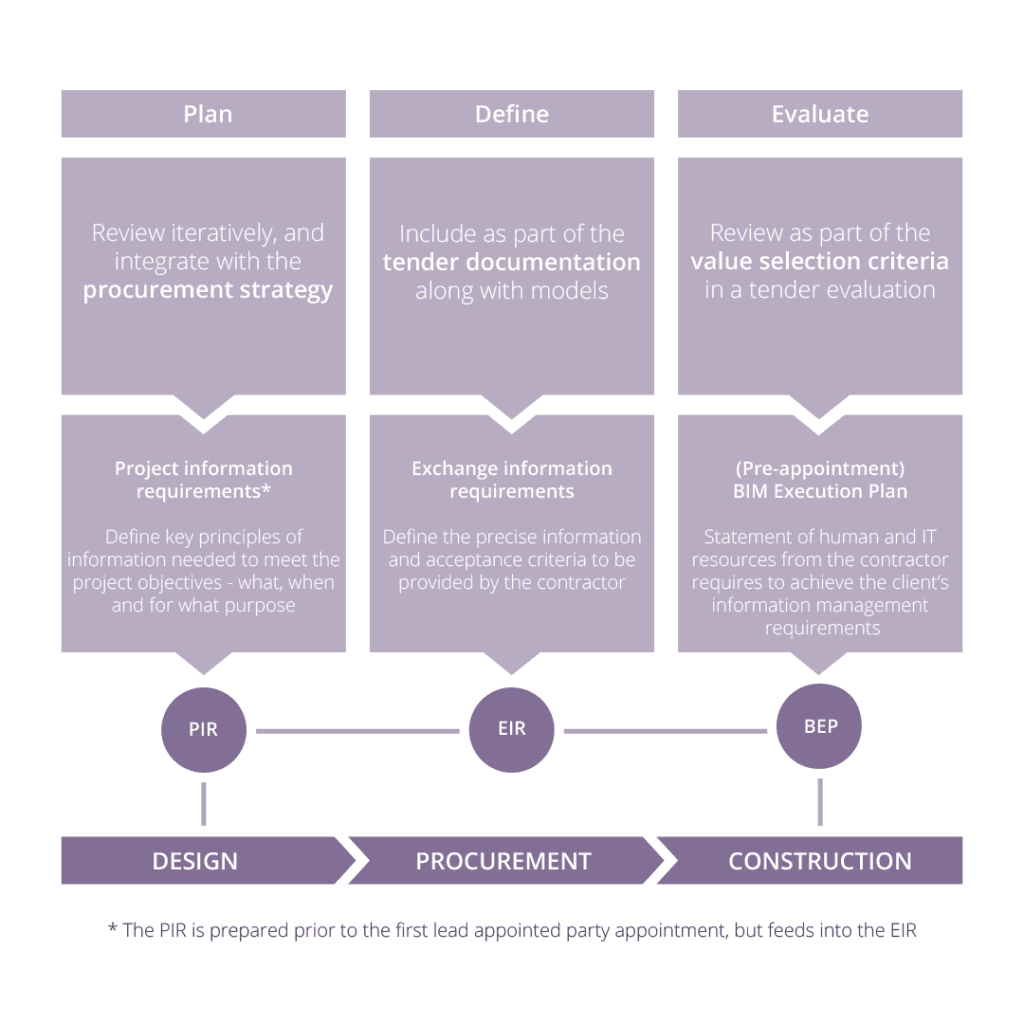

Although the project manager or quantity surveyor may not be responsible for producing the information protocol and supporting resources, they need to be able, and aware of how, to place them in the procurement process. Just as they would review a design before tender, a digitally aware surveyor needs to review the project information requirements (PIRs), exchange information requirements (EIRs) and pre-appointment BIM execution plan (BEP), as shown in Figure 2.

A role for digital twins?

To date, digital twins are most commonly used in the operation and maintenance phases of a project, to represent a physical asset and hone its performance. [1]

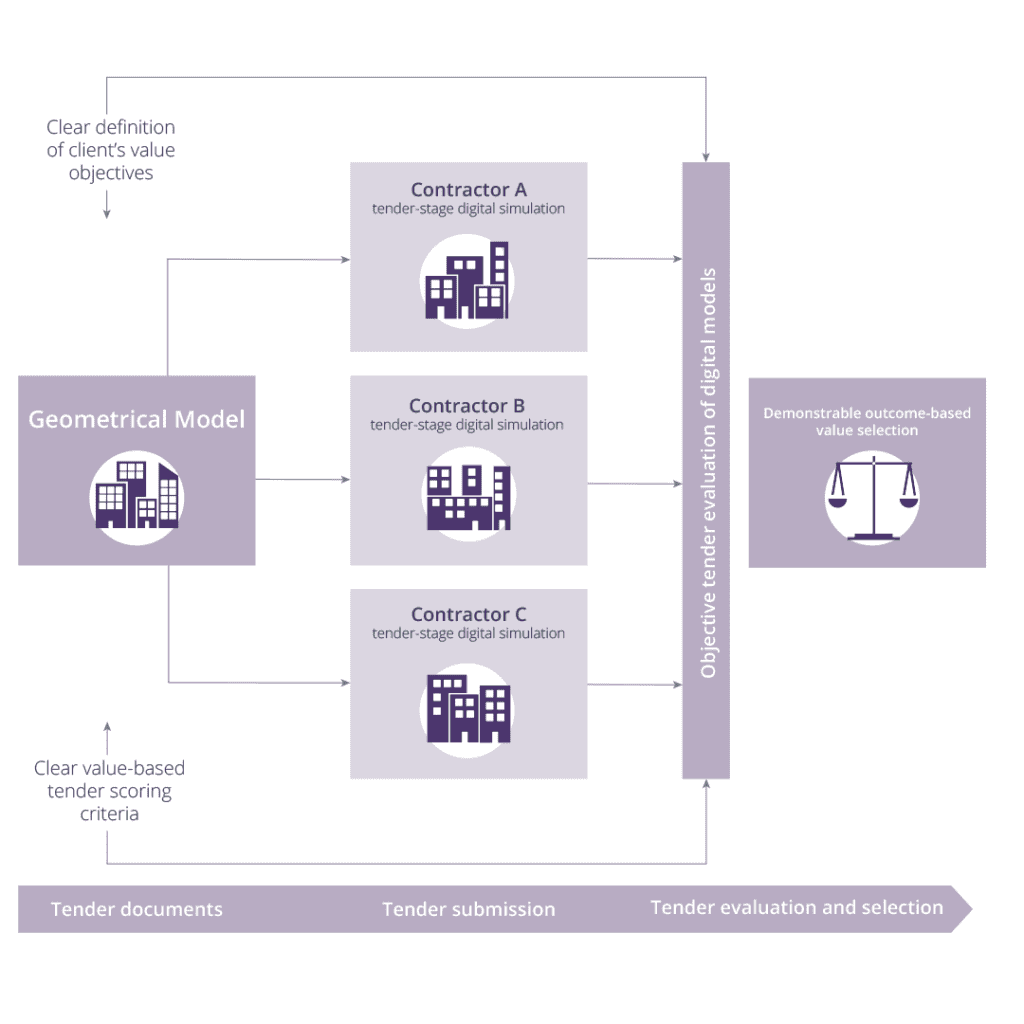

As contractors collect more data on sequencing, programme and productivity in real time and apply this to programming and cost-based models, though, it will be possible to run a digital simulation at tender stage. This will allow performance characteristics for the construction phase or the operational phase to be optimised.

If supply chain information on manufacturing and assembly characteristics – which helps optimise design for both of these – is layered on to this, it creates a powerful tender evaluation model for contractors and clients alike.

In time, clients will ask contractors for a tender-stage digital model submission for evaluation purposes. In this case, the contractor’s tender-stage model is an embryonic twin that can be compared to the design model and other submissions. As the project moves on to site, the model will become a fully-fledged digital twin to monitor performance in real time.

As the industry becomes enabled by big data, it will allow contractors to use information models to run tender-stage digital simulations of construction and operational performance and offer services that meet clients’ value objectives. If clients and their advisers are able to interrogate and compare these models, then the industry can achieve objective, outcome-based procurement.

Project managers and quantity surveyors can play their part by supporting their clients to embed information management and modelling into the procurement process and becoming more digitally literate. Ultimately, digitally enabled procurement will result in better tender returns and improved project performance.

An abridged version of this article originally appeared on the RICS Journal

FURTHER INFORMATION: